Electromobility has an essential role to play in the quest for a more sustainable future. In Germany, the number of electric cars has increased steadily over the last few years, exceeding one million vehicles for the first time in 2022. Worldwide, there are over 26 million cars on the road. One of the key technologies in electric vehicles is lithium-ion batteries — used to store energy, the increasing demand for electric vehicles has raised the question of the sustainability of the life cycle for these batteries.

The German Engineering Federation (VDMA) recently published an update of the “Roadmap Battery Production Equipment 2030”. The report makes clear that, in addition to technological aspects, the relevance of sustainability on the topic of battery production has only increased. This is particularly relevant to Europe. Fundamentally, the goal of electromobility is that it reduces CO2 emissions. As we know, the production of battery cells, including the raw materials used for them, is responsible for a large part of the environmental impact. Therefore, increasing material and energy efficiency in the production process must be essential.

This is where Munich-based start-up Tozero comes in. Sarah Fleischer, co-founder and CEO of the company, explains that her ambitious vision aims to reduce battery waste “to zero” with the help of a chemical recycling process. To achieve this, the start-up has opted for an innovative approach: Unlike the conventional pyrometallurgical process, they rely on the energy-saving and material-rich hydrometallurgical process.

The technology of battery recycling

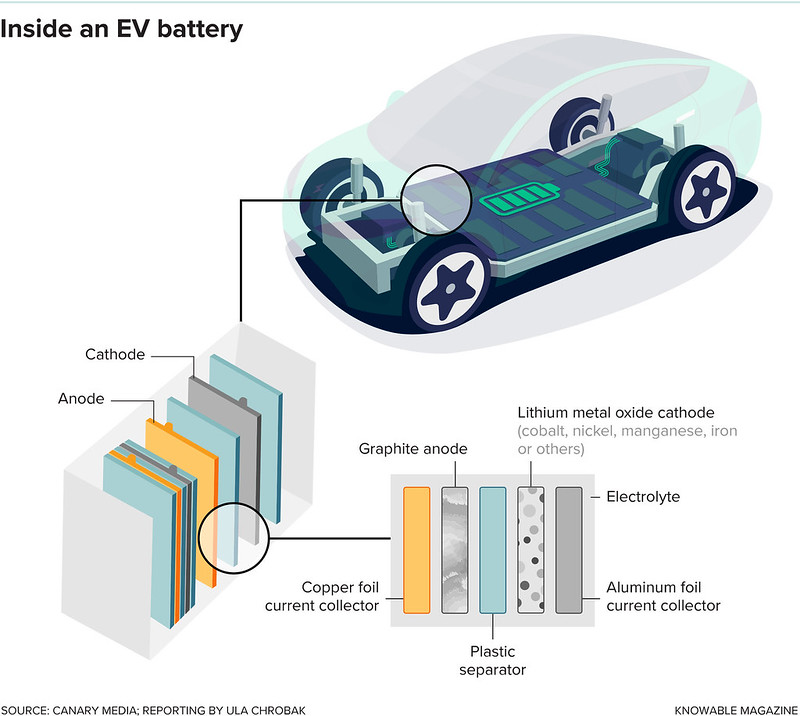

The recycling process of batteries involves several steps: First, the batteries are discharged, followed by disassembly, during which the outer casing is removed. The casing materials iron, aluminium and copper can already be recovered after this step. Subsequently, the inside of the battery is crushed into powder, whereby anode and cathode materials are recovered in the form of so-called “black mass”. This black mass contains valuable materials such as lithium, nickel, cobalt and manganese. The chemical reprocessing of this mass is the core of the hydrometallurgical process. Afterwards, processed materials can be reused unconditionally.

Recycling makes it possible to produce materials in Europe that would otherwise not be available. The largest cobalt reserves are in Congo, a politically unstable country. The most important producing countries for lithium are Chile, China and Australia. Increased recycling can reduce economic dependencies on the one hand. In addition, recycling batteries contributes to decarbonisation and makes it easier for companies to achieve their net-zero targets.

Fleischer sees the biggest challenge in the return of end-of-life products to the supply chain. Currently, there is no industrial solution to ensure the required recovery of materials according to European Union specifications. However, Tozero is working on enabling a closed material cycle.

The post The Path to Sustainable Battery Recycling: Tozero Wants to Bring “Batterywaste to Zero” appeared first on Digital for Good | RESET.ORG.