We have been seeing harvesting robots in the fields for several decades now. However, the existing models fertilise, pick and weed ripe crops with a metaphorical mallet rather than a velvet glove. Conventional agricultural robots have therefore so far been suitable for robust foods such as potatoes, cereals or beetroot, but not for produce that requires a lighter touch. However, pilot projects show that modern robotics will change this in the coming years.

The latest generation of robots uses sensors, cameras and AI software to carefully separate only ripe fruit from the plant. The picking robot from Floating Robotics manages to harvest tomatoes, for example, without damaging them in the process. At the same time, it has enough power to unfold fruit crates and transport them away for further processing. Its British brother from Fieldwork Robotics can even pick raspberries, which is a challenge even for humans.

The use of mechanical helpers in greenhouses and fields can reduce both the carbon footprint of agriculture and the use of pesticides. However, researchers also want to get prepared, in the worst-case scenario, global warming cannot be stopped sufficiently.

What are the differences between agricultural robots and conventional harvesting robots?

To understand why conventional agricultural vehicles are too coarse-engined for raspberries and tomatoes, we first need to look at our fields. A harvesting machine for potatoes is called a potato harvester. It tosses potatoes into a collecting device after ploughing the field. Modern versions can then immediately remove plant residues from the potatoes and then clean them thoroughly. Cameras and sensors are already being used here too.

Harvesting fields in this way has been possible with agricultural machinery for decades. Their development has gone from initial, purely mechanical harvesting tools to fully computerised machines. However, these machines have not yet been able to handle plants with enough sensitivity to not damage many in during harvest, or indeed to check whether they are even ready for harvest in the first place.

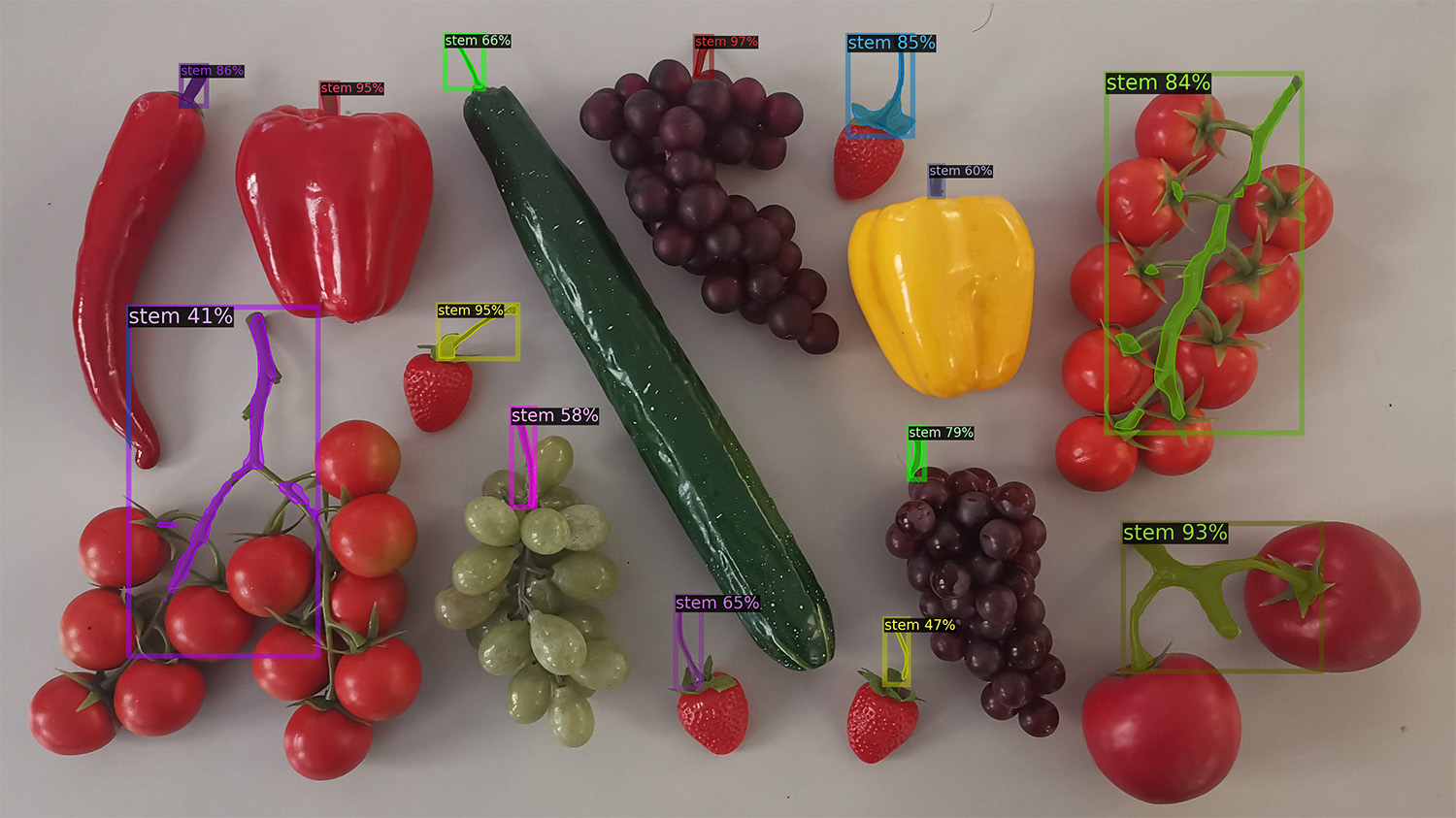

The harvesting robot from a subsidiary of ETH Zurich, on the other hand, processes data from a camera image with the assistance of AI. It detects differences in colour to identify which fruits are already ripe for harvesting. At the same time, it identifies the position of the tomatoes precisely enough to cut off the fruit just above the stem. The picking robot therefore not only protects the fruit, but also ensures the overall health of the plant. The robot then places the picked tomatoes in a collection basket and moves on to the next bush, all without the assistance of humans.

Useful in the greenhouse and the field

Floating Robotics would also like to use their machines in the fields. This should make the robots suitable for use in the open air as well as for vertical farming.

Floating Robotics places its picking robots on rails in greenhouses. There, the robotic arm, including the collection basket and required electronics, moves from plant to plant and removes the ripe fruit. The identification of ripe fruit and subsequent picking currently takes ten seconds for tomatoes. According to an information page on Floating Robotics, the process could be shortened to eight seconds for cherries. A faster system would result in the plants being damaged.

At the same time, the robot arm is strong enough to open plant crates. Human labourers therefore only have to take over the removal and quality assurance of the fruit and regularly provide empty crates for the robot.

In the field, the picking robot switches from the rail to tensioned ropes. The system is very reminiscent of the so-called “spider cams” familiar from football stadiums. Floating Robotics erects masts around a field and then attaches the hardware to steel cables between them. The robot is then free to move in three dimensions and is designed to bring the robot safely and precisely to the required location.

In addition to this solution, modern agricultural robotics research is also producing unusual solutions. The autonomous robot from Tevel Aerobotics Technologies relies on wired drones that can pick apples using suction cups. Although their propellers are protected by grids, the construction seems a little more fragile than cable technology.

But whether via drones or on a tightrope, using robots in the field could be a huge advantage.

Modern robots minimise the use of protective agents

Thanks to various attachments, harvesting robots can take on other tasks in agriculture. Their cameras already recognise diseases in plants and could instruct the robot to isolate them from other offshoots or treat them in a targeted manner. The use of pesticides should also be much more targeted than before thanks to the precise machines. Instead of spraying fields with pesticides across the board, nozzles spray them directly onto leaves or inject them into the plants’ growing medium.

This should make agriculture more sustainable in the future. According to the Federal Environment Agency, the widespread use of pesticides harbours the risk of them being washed away or drifting into nearby bodies of water. In addition, the intensive use of herbicides leads to a depletion of the plant world and deprives many deep-sea species of their food source. Furthermore, studies have shown that “pesticides are one of the main causes of the decline of various species of farmland birds, such as the skylark, yellowhammer and grey partridge, via the food chain”.

Robots could become a necessity in many places

In Central Europe, we have repeatedly measured record temperatures in the summer months in recent years. In addition, extreme weather phenomena such as droughts and floods are on the increase. The effects of global warming are even more noticeable in countries in the Global South. For farmers and field labourers, this makes work increasingly unbearable and sometimes even life-threatening.

Solar-powered agricultural robots such as the FD 20 from FarmDroid, on the other hand, benefit from direct sunlight. Thanks to an integrated battery that lasts overnight, farmers can use them around the clock for field work. They can conveniently control the robots themselves from their smartphone and only need to go to the field themselves in the event of a breakdown or problem. The same applies to the precise picking robots in greenhouses.

High temperatures are particularly stressful in greenhouses. While a hot, humid climate provides optimum growing conditions for various plants, the work here is particularly strenuous for people. Physical labour in such conditions is strenuous and can only be performed with sufficient breaks and short working hours. However, agricultural robots can work efficiently in hot environments – in principle even around the clock.

Advancing automation in agriculture also prevents another problem: The shortage of skilled labour, which will pose challenges for many sectors of the economy in the coming decades. This is mainly due to demographic developments, the effects of which will be exacerbated by rising temperatures. While there will be more and more old people, this population group will suffer particularly badly from high temperatures.

Agricultural robots still face a few hurdles

Even though developments in agricultural robotics are progressing rapidly, there are still some problems that need to be solved in the future. Probably the most serious is one that comes up in every discussion about automated vehicles.

Who takes responsibility if, for example, a field worker is injured by an autonomous field robot? This ethical question, which has been repeatedly discussed in recent years in connection with self-driving cars, will also arise in agriculture in the future.

Farmers who already work with such vehicles also criticise the frequent failures due to the poor coverage of the mobile phone network. Both mobile phone reception and GPS as a positioning system are also restricted by trees or buildings. However, these technologies mean that agricultural robots are primarily dependent on a digital infrastructure in the area of use. And this is not the case in many countries that are particularly affected by the consequences of climate change.

Developments interesting, but also dangerous

In a way, plants and agricultural robots have one thing in common: they benefit from the controlled conditions that can be created in greenhouses and vertical farms. As experts see them as a useful way of ensuring harvests even in areas with extreme weather conditions, the new developments in robotics are essential.

They could make the operation of greenhouses almost completely autonomous in the future. With increased efficiency, they could produce food in urban centres and represent an important tool in the fight against food shortages. After all, fields require a lot of space and are much harder to protect against environmental influences such as heat and flooding.

However, robot-assisted agriculture also comes with another risk. This is because the developments we have mentioned in this article usually cost five or even six-figure sums. The increasing use of agricultural robots is therefore also accompanied by the risk of increasing inequalities.

Therefore, substantial subsidies, grants and programmes are needed to prevent only rich companies from being able to produce food in the future.

The post The Rise of Precision Agricultural Robots Paving the Way for Delicate Crop Handling appeared first on Digital for Good | RESET.ORG.