The building sector is responsible for around 40 percent of CO2 emissions in Germany. It’s not just heating and cooling buildings that emit CO2. The choice of materials also affects the negative CO2 balance of our homes. Researchers are therefore looking for sustainable alternatives to concrete. Using a new process called “impact printing”, researchers at ETH Zurich claim to have found a way to use clay and earth for building houses.

A large 3D printer shoots materials out in a brick shape. They then fall from a height onto a substrate or other bricks. As well as reducing carbon emissions, impact printing has other advantages for the building industry.

Impact printing material can consist largely of waste

What is particularly exciting about impact printing is that it only requires a few composite materials. As the name suggests, the special 3D printer shoots the individual clay bricks onto a substrate or previously printed material. The individual parts hit each other with enough force that they firmly bond together.

What is “circular construction”?

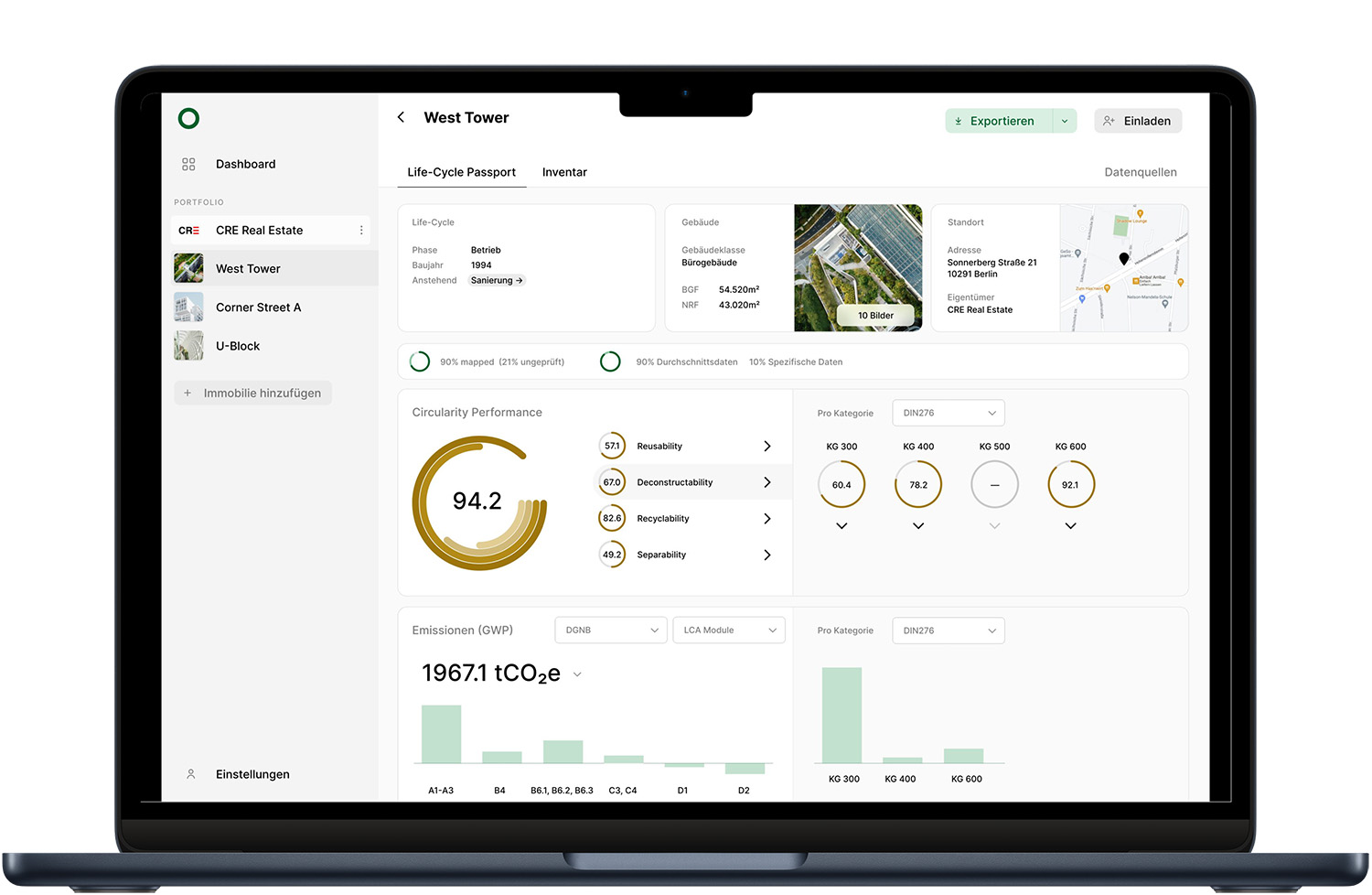

One exciting way to reduce the carbon footprint of buildings is circular construction. Engineers try to design buildings on the drawing board in such a way that they reuse materials from demolished buildings. At the same time, they plan circular buildings in such a way that they can be dismantled more easily in the future.

The German start-up Concular has developed the first certificates and an online marketplace for circular building materials. Read more in our article “Old Becomes New: Concular’s Mission to Digitise Circular Construction”.

The material used is a mixture of excavated material, silt and clay. According to Dr. Lauren Vasey, a postdoctoral researcher at ETH Zurich, the process is also suitable for circular construction methods for houses. For example, 75 percent of the mixture consists of ordinary industrial waste from the automation and assembly technology company “Eberhard AG”.

Devices are currently being developed and construction projects are already underway

ETH Zurich’s self-developed 3D printer, which can already print two-storey walls using impact printing, is currently running in a warehouse under laboratory conditions. In future, however, the researchers want to enable the printing process directly on construction sites using mobile 3D printers. The attachments developed for this purpose should be compatible with conventional construction vehicles such as excavators.

The ETH Zurich team has set itself the goal of developing further autonomous robots that give the 3D-printed structures more stability. They also smooth the surface of the walls and seal them against influences such as temperature and weather.

Such manufacturing processes can not only make the construction industry more sustainable but also less dependent on working hours and the availability of skilled workers. As the machines work autonomously around the clock, construction projects can be completed more quickly than using concrete.

Buildings are a CO2 heavyweight: the construction, heating, cooling and disposal of our homes accounts for around 40 percent of Germany’s CO2 emissions. We will only achieve our climate goals if these emissions are massively reduced.

But how can we achieve the sustainable transformation of buildings and what role do digital solutions play in this? The RESET Greenbook provides answers: Building transformation – intelligently transforming houses and neighbourhoods.

Using clay instead of concrete is just one of the ways that the building sector can become more sustainable. Other researchers are trying to grow buildings from mushrooms, for example, or reduce the amount of concrete used with the help of modern materials such as carbon fibres. We explain the opportunities that digitalisation offers for a successful building transition in our Greenbook “Building transition — intelligently transforming houses and neighbourhoods”.

The post Impact Printing: Will We Print Our Houses From Clay One Day? appeared first on Digital for Good | RESET.ORG.