Around 4.7 million tonnes of electronic waste are generated in Europe every year—an increase of 82% compared to 2010. And the demand for new electronics continues to rise in our increasingly digitalised world. A consistent circular economy is all the more important to make the electronics industry more sustainable. And with a new process, the Swiss start-up “REEcover” wants to make a particularly critical category of materials recyclable.

In Switzerland, less than one percent of rare earth metals are processed and reused to produce new electronics. Materials such as neodymium, scandium and europium are more common than their names suggest; however, extracting them is complex and has a major environmental impact. Rare earth metals occur naturally in mixed ores and must be separated from chemically similar materials to be recycled. Making this process more efficient is a compelling opportunity.

The first study promises a surprisingly high yield

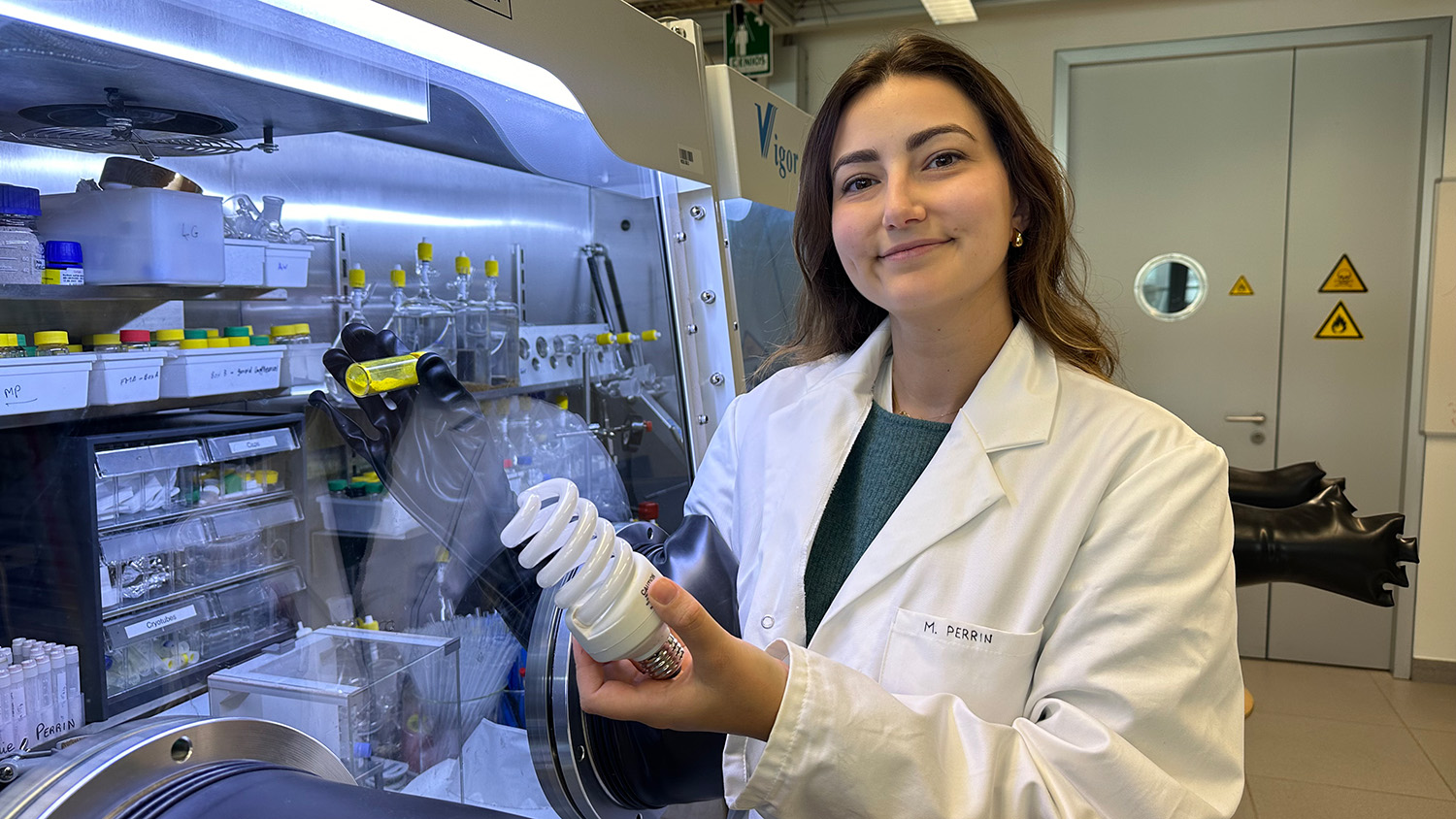

REEcover was founded by a group of researchers from ETH Zurich. In a study from 2024, they present a new process for separating europium from compounds such as those found in fluorescent lamps.

Marie Perrin, PhD student and first author of the study, describes the effectiveness of the new process in more detail in an article published by ETH Zurich. The researchers obtained around 50 times larger quantities of the material than it’s possible to obtain via conventional separation methods.

The team was inspired by proteins; in natural enzymes, tetrathiometallates are binding sites for metals. In the new separation process, these substances are used as ligands for europium. In simple terms, ligands are molecules that can bind other substances to them. By adding the metallates, the researchers can more easily separate the europium from other rare earth metals and then extract the material.

Victor Mougel, the head of the research group at ETH Zurich, describes this process as “significantly more environmentally friendly than all conventional methods for extracting rare earth metals from mineral ores”. This makes recycling rare earth metals more efficient than extracting them from nature.

The new method from REEcover could lead to further recycling success

The discovery of this new recycling process has come at an exciting time. Fluorescent lamps are now being replaced across the board by more efficient LED lamps, both in industry and in homes. As a result, the demand for fluorescent lamps is falling, meaning that recycling using conventional methods is becoming less economically viable.

Eric Schelter, a US professor of chemistry, sees a further advantage to the new recycling process. The results of the study could inspire researchers to develop new approaches to recycling rare earth metals. The REEcover team is now working on recycling other rare earth metals using similar separation processes. For example, they are trying to recover neodymium, which is used in items such as headphones, loudspeakers and microphones.

Overall, the recycling of europium via tetrathiometallates shows that implementing a circular economy can be significantly more efficient than extracting new raw materials from nature—and have major benefits for the environment and climate.

The post A Use for Electronic Waste: Start-up “REEcover” Wants To Make Rare Earth Metals Recyclable appeared first on Digital for Good | RESET.ORG.